Department of Manufacturing Technologists

Today, information technology is used to develop cutting-edge products such as self-driving cars, robots and drones. To realize these moving mechanisms, knowledge and skills in mechatronics, which integrates mechanical, electrical and electronic components, are important. The Department of Information Science and Mechatronics Engineering has a curriculum that teaches the fundamentals of mechatronics, such as machine design using 3D CAD, machining, materials science, electrical and electronic engineering, as well as programming techniques related to the fields of AI and information. In order to balance the learning of hardware and software, many ‘hands-on’ lessons are incorporated into the actual teaching and combined with classroom lectures to deepen understanding. Students can continuously learn ‘mechatronics using information technology’ by actually touching and making things.

Curriculums

The Institute has a well-balanced package of subjects necessary for manufacturing industrial products, including machinery, processing, design, materials, CAD, electricity, electronics, robot, computer, organizational management and safety management. In your junior year, you develop specialized knowledge in four model programs. In your junior and senior year, you can take the internship program in which you undergo on-the-job training at a company. In addition, you put much energy into special research and production activities for graduation in your senior year.

The Machine Design Program

How machines can work in harmony with people? Harmony between people and the environment, and not just the creation of “things,” will be required of manufacturing in the future. From this viewpoint, students in our machine design course will learn through hands-on-experience the basics of designing and manufacturing by acquiring the necessary knowledge and techniques related to machine elements, mechanical mechanics, material engineering, and machining processes. We aim for engineers who can form ideas that meet the needs of society.

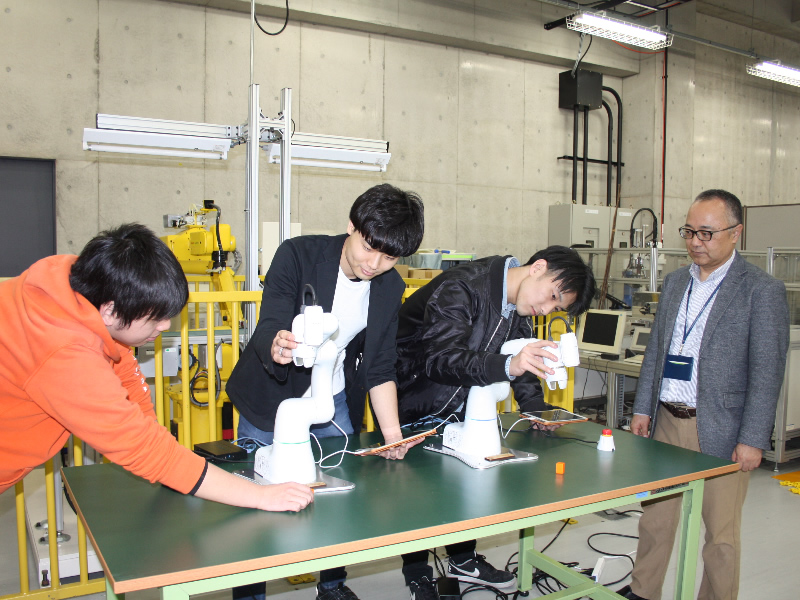

The Robotics System Program

Learn advanced technologies for control of high functioning robots and automated machines with the basics of mechatronics technologies such as mechanical systems, electronic circuits, and programming. The various learning contents cover sensors, actuators, microcomputers, software language, automation technology, and intelligent control. Acquiring integration technologies of information with machinery, and electronics that support the social infrastructure of the future are aims of this course.

AI / Information Systems Course

The technologies for detecting, analyzing and estimating various phenomena and moving things efficiently have advanced with the development of AI, IoT, and data science. In parallel, life-enhancing systems like autonomous driving, nursing care assistance, telemedicine as well as automation systems for manufacturing in agricultural, industrial, and construction machinery are quickly progressing. To learn the latest of these various technologies, we will study ICT in combination with AI, data science, and IoT, this course explores new manufacturing approaches in the AI era.

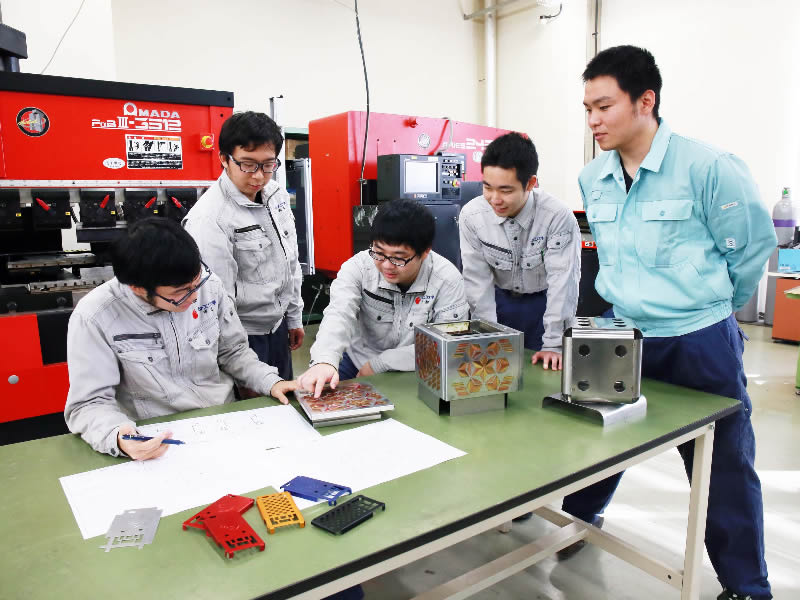

The Production Systems Course

Acquire the management techniques such as production line design, quality control and production and abilities to make proposals for an environment of efficient manufacturing based on basic machining technology. Our curriculum uses state-of-the-art tools and measurement equipment used in actual manufacturing sites, and our lectures by experienced teachers develop production engineers who are ready for action, attracting world-wide attention, and this course also features comprehensive study of manufacturing management with the Toyota Production System.

Student Activities

Our students design and produce robots and formula cars by putting their acquired knowledge and expertise to their utmost use and participate in special contests and competitions.